Product Description

Material | Virgin PTFE. Specified materials are also ok |

Color | Pure materials is White. Other color as order |

Method | Skiving and mould |

Certification | ISO9001, ISO14001, FDA, Rosh |

MOQ | 1kgs, specific szie according to stock |

Sample | Free |

Price | according to the specification and quantity, the more the cheaper. |

Package | Usually wooden case |

Others | Can filled with other materials to enhance performance |

The PTFE tubes are divided into three categories according to their processing technology: tubes with a diameter of 4mm-9mm are made by dispersing polymerized PTFE resin by paste pressing; tubes with a diameter of 10mm-50mm are selected as suspension PTFE. The resin is made by extrusion; the tube with a diameter of 50mm-300mm is made by molding.

PTFE is a polymer of tetrafluoroethylene. The relative molecular mass of PTFE is relatively large, hundreds of thousands of low, more than 10 million high, and generally millions. Typical crystallinity is 90%-95%, melting temperature is 327-342°C

Its frictional properties are extremely small, only 1/5 of polyethylene, which is an important feature of the surface of perfluorocarbon.

Polytetrafluoroethylene has low dielectric constant and dielectric loss over a wide frequency range, and high breakdown voltage, volume resistivity and arc resistance.

Compared with other plastics, PTFE has excellent chemical resistance and temperature resistance. It is widely used as sealing material and filling material. It has high chemical stability and excellent chemical resistance, such as strong acid resistance, strong alkali, strong oxidant, etc. It has outstanding heat resistance, cold resistance, abrasion resistance, excellent electrical insulation and is not affected by temperature.

Specification

Specification of PTFE tube

OD(mm) | Wall Thickness(mm) | Length(mm) | |

Paste Extruded Tube | 0.5~25 | 0.1~2.5 | According to customer's request |

Plug Extruded Tube | 25~250 | 1.5~8 | According to customer's request |

Molded Tube | 25~2000 | 5~500 | 100~300 |

Product Features

Main features of PTFE sheet :

1. Temperature resistance ---It is able to work stably between -180°C to +260°C.

2. Excellent chemical corrosion resistance ---Applicable medium includes oil, acid solution and almost all chemical materials.

3. Excellent non-sticky property - --With low friction coefficient it easier to remove those resin, dopes, oil and other sticky things.

4. Anti-aging, weathering resistance.

5. Excellent insulation property.

6. Filled material: Filled PTFE products has more outstanding performance by adding filler such as carbon, graphite, bronze, glass fiber, carbon fiber, MOS2, PEEK, PI, POB BaSO4, SiO2, glass bead, polyamide.

Technical datas of pure PTFE tube

Item | ASTM | Data | Unit |

Mechanical Properties | |||

Density | D792 | 2.1~ 2.2 | g/m3 |

Tensile strength | D638 | ≥25 about 25 ~ 45 | MPa |

Elongation at break | D638 | ≥150 about 200~ 350 | % |

Compression strength | D695 | 24 | MPa |

ShoreD Hardness | D636 | 50-60 | - |

Friction coefficient | on steel | 0.01 | - |

Thermal Properties | |||

Working Temp | -180 ~ 260 | °C | |

Melting point | 330 | °C | |

Produce Max. Temp | 390 | °C | |

Fire Resistance | UL94 | V-0 | |

Brittle point temperature | -268 | °C | |

Electrical properties | |||

Dielectric strength | D149 | >1400 | kV/mm |

Volume resistivity | D257 | >1018 | Ω·cm |

Surface Resistivity | D257 | >1016 | Ω |

Dielectric constant | D150 | 2.1 | |

Conventional properties | |||

Chemical solvent resistance | Excellent | ||

Water absorption (25℃ ) | D570 | 0.01 | 24h/% |

limit oxygen index | D2963 | >95 | |

Product Show

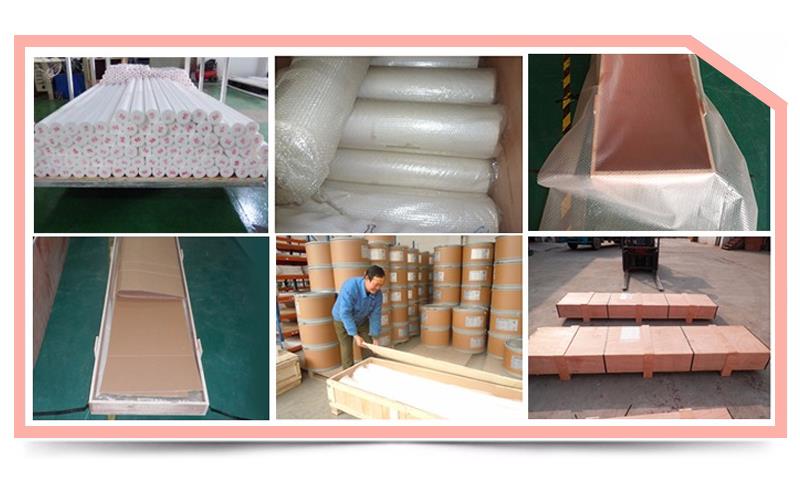

Product Packaging

Packed by plastic bags,put into Plywood cases that don't need fumigation. Other packing is customized according to client's requirements.